Feathures:

1. The machine structure is durable and has stable performance: it is made of 45# steel, which ensures strength and stability, effectively extending the service life of the machine; a strictly calibrated horizontal tooling platform is used during the steel processing to ensure that the mechanical structure is stable. , so that the unfired brick machine is evenly stressed during operation, reducing mechanical failures caused by high-frequency vibration during use, and the materials are evenly stressed during the production process, improving the density of the product.

2. The vibrating table has strong wear resistance: As an important working part of the brick-free brick machine, the vibrating table needs to withstand long-term and high-intensity vibration, so it is also an easily damaged part. In order to improve the fracture resistance and wear resistance of the vibrating table It uses special heat treatment processes such as high-frequency quenching to process it, which greatly extends the service life of the vibration table of the burn-free brick machine.

3. Intelligent electric box: The electrical components are selected from well-known German manufacturers such as Omron, Siemens, ABB, etc. to ensure the accuracy and convenience of the electric box; the operation interface is simple and clear, and different languages can be set according to customer needs, as much as possible. More convenience for customers.

Block machine specifications:

|

Dimension(L*W*H) |

3700×2030×2750mm |

Vibration force |

50KN |

|

Hydraulic pressure |

26Mpa |

Weight |

About 6.5T |

|

Moulding period |

15S |

Vibration Frequency |

Max.4600r/m |

|

Power |

30.2KW |

Pallet size(L*W) |

900x700mm |

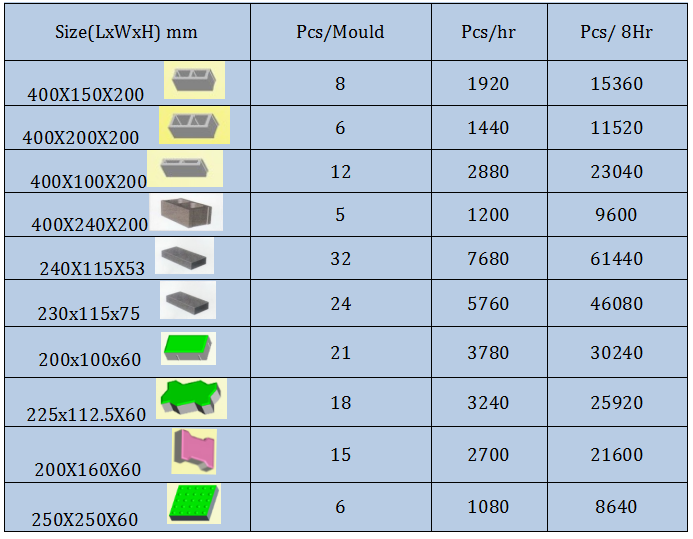

Capacity reference:

Contact 1:Frieda Sun

Tell:+86-15265911853(facebook,whatsapp)

Email:tianyuan@tianyuanzj.com

Contact 2:Wenhua Gao

Tell:+86-15216507718(facebook,whatsapp)

Email:service@tianyuanzj.com

Add:Da Zhuang Economic Development Zone, Linyi City, Shandong Province, China.